207615-7 TE Connectivity, 207615-7 Datasheet - Page 58

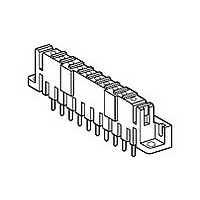

207615-7

Manufacturer Part Number

207615-7

Description

SKT HDR ASSY,16P,MMATE LF

Manufacturer

TE Connectivity

Type

Powerr

Datasheet

1.207615-7.pdf

(64 pages)

Specifications of 207615-7

Gender

SKT

Body Orientation

Straight

Housing Material

Nylon

Number Of Contacts

16POS

Number Of Ports

1Port

Number Of Terminals

16

Current Rating (max)

14/ContactA

Pitch (mm)

5mm

Contact Material

Phosphor Bronze

Operating Temp Range

-55C to 130C

Voltage Rating Max

600VDC/600VAC

Mounting Style

Through Hole

Termination Method

Solder

Contact Plating

Gold Over Nickel

Product Depth (mm)

11mm

Rohs Compliant

YES

Product Type

Connector

Connector Type

Header

Keyed

No

Mount

Printed Circuit Board

Pcb Mounting Orientation

Vertical

Mounting Ears

With

Post Type

Solder Post

Mating Connector Lock

Without

Pcb Mount Retention

With

Voltage (vac)

600

Current Rating (a)

14

Termination Post Length (mm [in])

4.72 [0.186]

Solder Tail Contact Plating

Tin over Nickel

Connector Configuration

In-Line

Number Of Positions

16

Coaxial Socket

Without

Centerline (mm [in])

5.00 [0.197]

Jackscrew

Without

8/32 Insert

No

Pcb Mount Retention Type

Mounting Holes

Contact Plating, Mating Area, Material

Gold (30)

Contact Base Material

Phosphor Bronze

Housing Color

Red

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Wave solder capable to 240°C, Wave solder capable to 260°C, Wave solder capable to 265°C

Rohs/elv Compliance History

Always was RoHS compliant

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

207615-7

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

111

58

Crimp Quality Monitor

(CQM)

Part No. 1320420-2

AMP 3K/40 and AMP

5K/40 Terminating

Machines

Catalog 82045

Revised 06-08

www.tycoelectronics.com

Dimensions are in millimeters

and inches unless otherwise

specified. Values in brackets are

equivalent U.S. Customary Units.

Application Tooling

AMP Metrimate

Pin and Socket Connectors

The unique system pro-

vides 100% on-the-fly crimp

inspection. It measures the

crimp height of each termina-

tion, and evaluates the quality

of each crimp. If a crimp is

questionable, the monitor

alerts the operator with both

visual and audible alarms. It

also provides ports for print-

ing and networking. When

used with AMP-O-LECTRIC

Model “G” Termination Ma-

chines, the monitor is mount-

ed to the machine. When

used with AMPOMATOR CLS

IV Lead Making Machines, it is

integrated into the machine’s

operating system.

For more information, request

Catalog 82275.

The AMP 3K/40 and AMP

5K/40 Terminators are

designed for customers

that require the increased

output and quality of a

semiautomatic machine

at a competitive price. By

incorporating the most

commonly requested

features as standard and

offering a long list of optional

equipment, these terminators

offer flexibility to meet the

specific needs of various

applications at the lowest

possible cost.

Features

•

•

•

•

•

•

•

For more information, request

Catalog 1654956-2.

Note: New Stripping Module

available, see page 79.

3,000 lb [1361 kg] max.

crimp force (AMP 3K/40);

5,000 lb [2268 kg] max.

crimp force (AMP 5K/40)

Toolless removal of

applicators and guards

Jog capability

Quiet, fast operation -

80/76 dBA and cycle time

less than 0.400 seconds

Accepts Heavy Duty Mini

stye applicators

Wide range of optional

equipment such as toolless

precision crimp height

adjust, batch counter, CQM

capability and work light

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

(Continued)

Crimp Force Monitor

(CFM)

Your Quality Program

calls for more than a

Good Crimping System. It

demands proof — the proof

you get with the SLE crimp

force monitor. It has high-

resolution piezo-quartz

sensor technology for a

more precise identification of

typical crimping faults.

Sure, you can sample and

test crimp height with a

micrometer. In fact, that’s

how you standardize your

process. But for ongoing

quality control, testing every

crimp, SLE is the choice.

It’s known worldwide, and

meets our standards or a

high performance terminating

system. That’s how you can

be sure.

High quality crimping — with

verification — means higher

production and productivity.

System III Applicator

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

NOTE: All part numbers

are RoHS Compliant

Features

• 1 or 2 Channels

• 128 x 128 Dot Matrix

• Zone & Peak Force

• Force Trigger

• Encoder Proximity Trigger

• Absolute Force

• Monitors the wire barrel

• Real-time monitoring of

• Special applicators are not

• Use with the AMP-3K/40

• Frame-mounted force

• For bench or fully-

• Please contact us for any

Crimp Force Monitor

Specifications

• Electrical: 110-230 VAC

• Size (Monitor): 178mm x

• Weight (Monitor): 1.02kg

For more information, request

Catalog 1309085-2

The System III Applicator

introduces several new tech-

nologies into the applicator

including a precision servo-

electric motorized feed-

ing system, a built-in data

module for storing terminal

crimp and set-up information,

a precision fit round ram, and

a newly designed terminal

depressor. It still utilizes the

proven quality of the HD-M

crimper and anvil tooling.

For more information, request

Catalog 1654956-8

Analysis

Measurement

crimp of open-barrel,

uninsulated contacts and

terminals

every crimp

required

and AMP-5K/40 presses

from Tyco Electronics

sensor

automatic machines

other type of press you

would like to use with the

CFM

Single Phase, 50-60 Hz, 15

watts

137mm x 95mm

(single channel), 1.05kg

(double channel)

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967