201358-1 TE Connectivity, 201358-1 Datasheet - Page 5

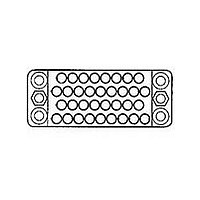

201358-1

Manufacturer Part Number

201358-1

Description

RECTANGULAR HOUSING, PLUG, 50WAY

Manufacturer

TE Connectivity

Type

Housingr

Series

Mr

Specifications of 201358-1

Number Of Contacts

50POS

Number Of Contact Rows

4

Body Orientation

Straight

Pitch (mm)

3.81mm

Gender

PL

Housing Material

Phenolic

Operating Temp Range

-55C to 150C

Housing Color

Black

Product Height (mm)

19.05mm

Product Depth (mm)

23.52mm

Product Length (mm)

56.91mm

No. Of Contacts

50

No. Of Rows

4

Pitch Spacing

3.81mm

Contact Gender

Pin

Connector Mounting

Cable

Peak Reflow Compatible (260 C)

No

Connector Type

Rectangular Power

Rohs Compliant

Yes

Agency Approvals

CSA, UL

Angle

Straight

Brand/series

M Series

Color

Black

Color, Housing

Black

Flammability Rating

UL94V-0

Length, Overall

2.595 "

Material, Housing

Phenolic

Mounting Type

Free Hanging, Panel Mount

Number Of Positions

50

Primary Type

Interconnect System

Standards

RoHS and ELV Compliant

Temperature, Operating

-55 to +150 °C

Product Type

Housing

Type Of Connector

Standard

Mount

Free Hanging, Panel

Mounting Hardware

None

High Voltage

No

Center Fastener

No

Connector Style

Plug

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Wave solder capable to 240°C, Wave solder capable to 260°C, Wave solder capable to 265°C

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

For Use With

Type II, type III+ and subminiature coaxicon contacts

Catalog 82003

Revised 06-08

www.tycoelectronics.com

Dimensions are in millimeters

and inches unless otherwise

specified. Values in brackets are

equivalent U.S. Customary Units.

AMP M Series

Pin and Socket Connectors

Introduction

What makes the M Series

connector line so versatile

and special for a wide variety

of applications?

•

•

•

•

•

How to choose the appropri-

ate connector/contact/

hardware combination

Choosing the appropriate con-

nector/contact/hardware

combination is essential to the

proper function of any

AMP M Series connector. First,

a customer must evaluate

each individual application

with regards to: wire size(s);

number of circuits; available

space; fastening methods; and

needs for protection, shielding,

guiding, strain relief and key-

ing. Then, the customer must

consider the following factors

to make the appropriate selec-

tion of M Series connectors

and related components.

Compatibility

connectors intermateable

with connectors made to

MIL-C-28748 requirements.

Wide range

nector styles and sizes:

standard connectors

(unloaded), posted connec-

tors (preloaded) and special

application connectors.

Complete line

accessory hardware for fas-

tening, protecting, guiding,

strain relief and keying.

Variety of contacts

power, coaxial, and posted

versions—many are inter-

changeable and can be

intermixed in the same con-

nector housing.

Full complement of applica-

tion tooling–For wire crimp

and posted terminationshand

tools, semiautomatic tooling

and fully automatic machines

provide highly reliable, low

cost terminations to meet

production requirements.

–Choice of con-

–Most

–Full line of

(Continued)

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

–Signal,

A - Determine Connector Type–

This decision is based on the

selected contact types, circuit

density requirements and, if

posted connectors are desired,

in-plant production capabilities

for wiring connectors using

hand tools or semiautomatic

tooling. Detailed specifications

of the various M Series connec-

tors are presented on the

following pages: Standard con-

nectors (pages 44 through 51),

Posted connectors (pages 52

through 60), Special

Application connectors (pages

61 through 77).

B - Determine Hardware–

This decision is based on the

selected connector types, and

the individual application

requirements for fastening, pro-

tection, shielding, guiding, strain

relief and keying. To assist cus-

tomers in determining the

proper hardware to use, hard-

ware selection information has

been formulated for each con-

nector type. This information is

located on pages 10 through 25.

Complete specifications of each

hardware component are pre-

sented in the Hard-ware section

of the catalog (pages 78

through 89).

C - Determine Contact Type –

This decision is based on wire

size(s) and reliability and cost

requirements of an application,

as well as the customer’s in-

plant production capabilities.

Complete specifications, includ-

ing accepted wire sizes and

available platings of all pin and

socket contacts, are presented

in the Contacts section of the

catalog (pages 30 through 43).

Application tooling for crimp-

and post-type contacts is

presented on pages 90 and 91).

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

NOTE: All part numbers

are RoHS Compliant

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

5