CY7C68014A-56BAXC Cypress Semiconductor Corp, CY7C68014A-56BAXC Datasheet - Page 59

CY7C68014A-56BAXC

Manufacturer Part Number

CY7C68014A-56BAXC

Description

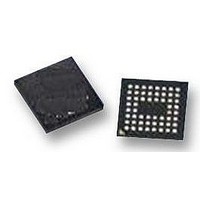

IC MCU USB PERIPH HI SPD 56VFBGA

Manufacturer

Cypress Semiconductor Corp

Series

EZ-USB FX2LP™r

Specifications of CY7C68014A-56BAXC

Applications

USB Microcontroller

Core Processor

8051

Program Memory Type

ROMless

Controller Series

CY7C680xx

Ram Size

16K x 8

Interface

I²C, USB, USART

Number Of I /o

24

Voltage - Supply

3 V ~ 3.6 V

Operating Temperature

0°C ~ 70°C

Mounting Type

Surface Mount

Package / Case

56-VFBGA

Core Size

16bit

No. Of I/o's

24

Program Memory Size

16KB

Ram Memory Size

16KB

Cpu Speed

48MHz

Oscillator Type

External Only

No. Of Timers

3

Digital Ic Case Style

VFBGA

Supply Voltage Range

3V

Controller Family/series

EZ-USB FX2LP

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With

CY4611B - KIT USB TO ATA REFERENCE DESIGN

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

CY7C68014A-56BAXC

Manufacturer:

Cypress Semiconductor Corp

Quantity:

10 000

from the thermal pad to the PCB inner ground plane by a 5 x 5

array of via. A via is a plated through hole in the PCB with a

finished diameter of 13 mil. The QFN’s metal die paddle must

be soldered to the PCB’s thermal pad. Solder mask is placed

on the board top side over each via to resist solder flow into

the via. The mask on the top side also minimizes outgassing

during the solder reflow process.

For further information on this package design please refer to

the application note Surface Mount Assembly of AMKOR’s

MicroLeadFrame (MLF) Technology. This application note can

be downloaded from AMKOR’s website from the following

URL

http://www.amkor.com/products/notes_papers/MLF_AppNote

_0902.pdf. The application note provides detailed information

on board mounting guidelines, soldering flow, rework process,

etc.

Purchase of I

I

as defined by Philips. EZ-USB FX2LP, EZ-USB FX2 and ReNumeration are trademarks, and EZ-USB is a registered trademark,

of Cypress Semiconductor Corporation. All product and company names mentioned in this document are the trademarks of their

respective holders.

Document #: 38-08032 Rev. *K

© Cypress Semiconductor Corporation, 2006. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use

of any circuitry other than circuitry embodied in a Cypress product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor intended to be

used for medical, life support, life saving, critical control or safety applications, unless pursuant to an express written agreement with Cypress. Furthermore, Cypress does not authorize its

products for use as critical components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress

products in life-support systems application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress against all charges.

2

C Patent Rights to use these components in an I

2

C components from Cypress, or one of its sublicensed Associated Companies, conveys a license under the Philips

Via hole for thermally connecting the

QFN to the circuit board ground plane.

Figure 14-1. Cross-section of the Area Underneath the QFN Package

PCB Material

Figure 14-2. Plot of the Solder Mask (White Area)

Figure 14-3. X-ray Image of the Assembly

Cu Fill

2

C system, provided that the system conforms to the I

Solder Mask

0.013” dia

0.017” dia

Figure 14-1 below displays a cross-sectional area underneath

the package. The cross section is of only one via. The solder

paste template needs to be designed to allow at least 50%

solder coverage. The thickness of the solder paste template

should be 5 mil. It is recommended that “No Clean” type 3

solder paste is used for mounting the part. Nitrogen purge is

recommended during reflow.

Figure 14-2 is a plot of the solder mask pattern and

Figure 14-3 displays an X-Ray image of the assembly (darker

areas indicate solder).

This figure only shows the top three layers of the

circuit board: Top Solder, PCB Dielectric, and

the Ground Plane

Cu Fill

PCB Material

CY7C68013A/CY7C68014A

CY7C68015A/CY7C68016A

2

C Standard Specification

Page 59 of 60