CCM04-1889LFT R102 C&K Components, CCM04-1889LFT R102 Datasheet - Page 9

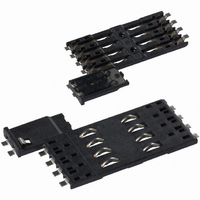

CCM04-1889LFT R102

Manufacturer Part Number

CCM04-1889LFT R102

Description

CONN SMART CARD LOW PRO 8PIN SMD

Manufacturer

C&K Components

Series

CCM04 MK IIr

Type

SIMr

Specifications of CCM04-1889LFT R102

Card Type

Smart Card

Number Of Positions

10 (8 + 2)

Connector Type

Connector

Insertion, Removal Method

Push In, Pull Out

Mounting Type

Surface Mount, Right Angle

Features

Switch

Height Above Board

0.083" (2.10mm)

Mounting Feature

Normal, Standard - Top

Contact Finish

Gold

Gender

M

Mounting Style

Surface Mount

Termination Method

Solder

Body Orientation

Straight

Contact Pitch (mm)

2.54mm

Housing Material

Thermoplastic

Number Of Contact Rows

2

Number Of Contacts

8POS

Current Rating (max)

1A

Contact Material

Copper Alloy

Operating Temp Range

-40C to 85C

Product Height (mm)

2.2mm

Product Depth (mm)

28mm

Product Length (mm)

16.2mm

Product

Card Connectors

Pitch

2.54 mm

Termination Style

Solder Tail

Number Of Rows

2

Current Rating

1 mA

Contact Plating

Gold

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Contact Finish Thickness

-

Ejector Side

-

Lead Free Status / RoHS Status

Not Compliant, Lead free / RoHS Compliant

Other names

401-1730-2

CCM04-1889 LFT

CCM04-1889LFT

Y1142-1889A LFT

CCM04-1889 LFT

CCM04-1889LFT

Y1142-1889A LFT

CCM03 MK II

A new range of CCM03 connectors

have been developed to interface with

SIM/SAM cards as defined by GSM11-

11 and ENV1375-1. The connectors are

available with either hinged covers or

fixed covers and have been designed to

minimize the amount of space needed

for PCB mounting.

Features

• Available with 6 or 8 contacts, with or

• Available with insulated card presence

• The cover springs open when

• The molding is polarized so that the

• The cover can be replaced without

• Inspection slots allow an electrical test

• The overall height of the connector is

• Available with 6 or 8 contacts.

• The overall height of the connector is

• With tape and reel packaging as stan-

• The high temperature thermoplastic

• By using an inlay finish in the contact

• Robustly formed printed circuit tails

without PCB locating pegs.

switch.

unlocked while the card is in place.

cover can only be closed if the card is

correctly inserted.

removing the connector from the PCB.

to be made without opening the cover.

only 2,5 mm. The amount of space

needed to mount the connector is just

29,65 mm x 17,2 mm.

2,85 mm max. Only 25,5 mm x 17,2

mm of board space is required to

mount the connector.

dard, the connectors are designed to

be automatically pick-and-placed.

moldings are suited for infrared and

convection soldering processes.

area the life of the precious metal is

extended by over 10 times that of

standard gold plating.

allow a co-planarity of ± 0,05 mm to

be maintained.

Hinged Cover

Fixed Cover

General

Contacts

Plating

Moldings

Slide lock/metal cover

Number of Contacts

Mechanical life, hinged cover

Mechanical life, fixed cover

Card insertion force

Card extraction force

Contact force

Slide locking force

Vibration

Shock

Insulation resistance

Resistance

Current rating

Dielectric strength

Card detection switch

Contact resistance

Dielectric strength

Current rating

Maximum power

Operating temperature

Soldering temperature

Damp heat

Salt mist

Quantity per reel, see table next page.

Contact Electrical Data

Packaging

Switch Electrical Data

Environmental Data

Construction

Mechanical Data

12

Copper alloy

Contact area : Gold alloy inlay or gold over nickel

Terminals : Tin lead (2µ min)

High temp. thermoplastic UL 94V-0 rated

Stainless steel

6 or 8

10,000 cycles min

50,000 cycles

Hinged cover: 1 N max

Fixed cover: 3 N max

Hinged cover: 1 N max

Fixed cover: 0.80 N min / 3 N max

0.25 N min / 0.50 N max

2 N min / 6 N max

Frequency 10 to 500 Hz. Acceleration 50m/s

Duration 6 hours - amplitude 0,35 mm

Max electrical discontinuity 1µs

Peak value 500 m/s

3 shocks in each direction of each axis

Max electrical discontinuity 1 µs

1,000 MΩ min

100 mΩ max

10 µA min / 1 A max

750 Vrms min

Normally open

100 mΩ max

250 Vrms min

1 mA min / 10m A max

0.2 VA

-40°C to +85°C

Temperature/time profile acc. to CECC00802

para. 6.1, Fig. 3 with peak temperature 250°C

IEC 512 test number 11c (10 days)

IEC 512 test number 11f (96 hours)

Specifications and dimensions subject to change

www.ck-components.com

2

– Duration 11 ms

Dimensions are shown in mm

2