BR1225 RAYOVAC, BR1225 Datasheet - Page 3

BR1225

Manufacturer Part Number

BR1225

Description

LITHIUM BATTERY, 3V, COIN CELL

Manufacturer

RAYOVAC

Datasheet

1.BR1225.pdf

(26 pages)

Specifications of BR1225

Battery Size Code

Coin Cell

Battery Capacity

50mAh

Battery Voltage

3V

Battery Technology

Lithium

Battery Terminals

Pressure Contact

External Diameter

12.5mm

External Height

2.5mm

Lead Free Status / RoHS Status

na

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

BR1225

Manufacturer:

MAXWELL

Quantity:

4 000

Company:

Part Number:

BR1225-1VC

Manufacturer:

STANLEY

Quantity:

3 000

Company:

Part Number:

BR1225/1HC

Manufacturer:

SMSC

Quantity:

3 000

Company:

Part Number:

BR1225/H1A

Manufacturer:

TAIYO

Quantity:

4 000

Company:

Part Number:

BR1225A/HBN

Manufacturer:

Panasonic

Quantity:

4 000

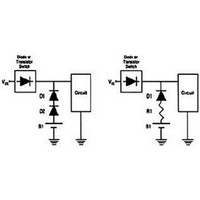

VII. Calculating Battery Life

The design of an electronic circuit powered by a

component class battery requires the designer to

consider two interacting paths that determine a

battery’s life: consumption of active electro-

chemical components and thermal wear-out.

To optimize battery life in powered devices, today’s

designers are first selecting power conserving

circuit components, and then specifying high

reliability component Lithium batteries. Battery

selection is based on an understanding of the

thermal capabilities, effects of the operating

environment, and the battery life requirements of

the powered device.

Figure 1, at right, gives an estimate of years of

service at various discharge currents for BR

Lithium coin cells at room temperatures.

Consumption of Active Battery Components

Batteries produce electrical current by oxidation

and reduction of their active electrochemical

components. Once these components are

consumed, the battery ceases to produce current.

The sum of the energy consumed by the circuit

over its expected life plus the electrochemistry’s

inherent loss of energy due to self-discharge,

represents the first path in determining battery life.

Thermal Wear-Out

The second path in determining battery life is

thermal wear-out, which is the loss of capacity

caused by thermal mechanisms. Generally, thermal

wear-out rates accelerate as temperatures in the

operating environment rise.

It is very important to hold the paths of self-

discharge and thermal wear-out as separate issues.

This is because self-discharge can sometimes be

compensated for by increasing the specified

battery capacity, while thermal wear-out can only

be addressed by selecting a more thermally

capable battery.

3

Battery Life and Capacity Estimates

Rayovac has accumulated over 200 million device

hours of accelerated reliability testing with a major

semiconductor manufacturer. This data has

allowed us to gain a better understanding of the

time and temperature dependent wear-out of BR

Lithium coin cells and FB batteries during storage.

Please contact Rayovac's OEM Division for more

information.

0.4

20

10

1

0.1

BR2325

Discharge Current (µA)

Drain vs. Duration

BR1225

1

Figure 1

10

BR2335

BR2032

BR1632

100