BR1225 RAYOVAC, BR1225 Datasheet - Page 23

BR1225

Manufacturer Part Number

BR1225

Description

LITHIUM BATTERY, 3V, COIN CELL

Manufacturer

RAYOVAC

Datasheet

1.BR1225.pdf

(26 pages)

Specifications of BR1225

Battery Size Code

Coin Cell

Battery Capacity

50mAh

Battery Voltage

3V

Battery Technology

Lithium

Battery Terminals

Pressure Contact

External Diameter

12.5mm

External Height

2.5mm

Lead Free Status / RoHS Status

na

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

BR1225

Manufacturer:

MAXWELL

Quantity:

4 000

Company:

Part Number:

BR1225-1VC

Manufacturer:

STANLEY

Quantity:

3 000

Company:

Part Number:

BR1225/1HC

Manufacturer:

SMSC

Quantity:

3 000

Company:

Part Number:

BR1225/H1A

Manufacturer:

TAIYO

Quantity:

4 000

Company:

Part Number:

BR1225A/HBN

Manufacturer:

Panasonic

Quantity:

4 000

E. Disposal

This statement is provided as a service to those

who may want information concerning the safe

disposal of waste Rayovac BR and FB (Lithium

Carbon-monofluoride) battery products for the

USA. These products may be distinguished from

other battery products by the presence of the

letters BR or FB in the product designation, and are

manufactured in a disk or "coin" shape and square

modules.

This information does not apply to any other

Lithium chemistry or Lithium Carbon-monofluoride

products in other form factors.

Note: Where regulations regarding management of

spent/waste Lithium batteries exist outside of the

USA, they generally differ significantly from United

States regulations. For information regarding

recommended disposal and management practices

in regions or countries other than the USA, please

contact Rayovac at 1-800-237-7000 within the

USA, or 608-275-3340 if outside the USA and ask

for Tim Anderson.

Regarding Rayovac BR Lithium cells and FB

Lithium battery waste battery management in the

USA:

Waste BR Lithium cells and FB Lithium batteriess

are neither listed nor exempted from the USEPA

hazardous waste regulations. Waste BR and FB

Lithium products can be considered reactive

hazardous waste if there is a significant amount of

unreacted, or unconsumed Lithium remaining. This

potential problem may be avoided by discharging

waste cells and batteries prior to disposal. One

tested method for doing this is to place small

quantities of BR Lithium cells or FB Lithium

batteries into a metal container with sufficient

graphite to cover and surround the individual cells.

This procedure will discharge the cells in

approximately two weeks to the point where no

reactive Lithium remains. The cells may then be

disposed of as nonhazardous waste in an ordinary

landfill under Federal regulations. The graphite can

be reused many times, as needed, or can be

disposed of as nonhazardous waste.

23

Other Disposal Methods

For a list of facilities with demonstrated ability to

manage waste BR Lithium cells and FB Lithium

battery products as hazardous waste, please click

here. The list is not guaranteed to be all inclusive,

nor does it seek to exclude potential service

suppliers. Rayovac provides it as a customer

service to assist the customer in determining what

their management options could be. Always review

your choice of firm before sending wastes.

Cautions

Under United States Federal law, waste generators

are responsible for their wastes. Be sure to check

your regional, national, or local regulations as they

may differ significantly. Always remember that

waste battery products may still have considerable

energy remaining in them. Handle such products

with care and in accordance with applicable

USDOT, IATA, or ICAO regulations.

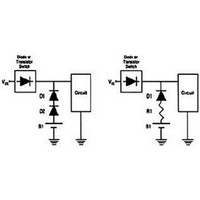

F. Soldering

Rayovac's BR and FB component class Lithium

batteries are suitable for direct soldering onto

printed circuit boards (PCB). A welded tab or pin

soldered to a PCB will ensure the highest contact

reliability available. Observe these precautions to

assure life-of-product reliability:

1.Hand Soldering

2.Wave Soldering

Never solder directly to cell cases. The resultant

heat will cause permanent internal damage to the

cell. Soldering of tabbed batteries should be

accomplished with a low wattage soldering iron

by applying heat just long enough to achieve a

good connection.

During the period when the battery tabs or pins

are in the solder bath, the battery is short

circuited. If this period is kept to under 5

seconds the battery capacity loss will be

minimized. Following a short circuit the battery

voltage will recover to above 2.5 volts almost

immediately while full recovery to its final

working voltage may take hours or even days.

This characteristic must be taken into account

when making electrical measurements on

recovering batteries or when establishing

manufacturing pass/fail points.