LF398M/NOPB National Semiconductor, LF398M/NOPB Datasheet - Page 7

LF398M/NOPB

Manufacturer Part Number

LF398M/NOPB

Description

IC AMP MONO SAMPLE & HOLD 14SOIC

Manufacturer

National Semiconductor

Datasheet

1.LF398NNOPB.pdf

(13 pages)

Specifications of LF398M/NOPB

Amplifier Type

Sample and Hold

Number Of Circuits

1

Current - Input Bias

10nA

Voltage - Input Offset

2000µV

Current - Supply

4.5mA

Voltage - Supply, Single/dual (±)

±5 V ~ 18 V

Operating Temperature

0°C ~ 70°C

Mounting Type

Surface Mount

Package / Case

14-SOIC (3.9mm Width), 14-SOL

Acquisition Time

4 us

Maximum Operating Temperature

+ 70 C

Minimum Operating Temperature

0 C

Supply Voltage (max)

18 V

Supply Voltage (min)

5 V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Output Type

-

Current - Output / Channel

-

-3db Bandwidth

-

Slew Rate

-

Gain Bandwidth Product

-

Lead Free Status / Rohs Status

Details

Other names

*LF398M

*LF398M/NOPB

LF398M

*LF398M/NOPB

LF398M

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

LF398M/NOPB

Manufacturer:

NS/国半

Quantity:

20 000

Application Hints

(Continued)

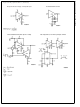

Guarding Technique

logic input for signal delay, calculate the slope of the wave-

form at the threshold point to ensure that it is at least

1.0 V/µs.

Sampling Dynamic Signals

Sample error to moving input signals probably causes more

confusion among sample-and-hold users than any other pa-

rameter. The primary reason for this is that many users make

the assumption that the sample and hold amplifier is truly

locked on to the input signal while in the sample mode. In ac-

tuality, there are finite phase delays through the circuit creat-

ing an input-output differential for fast moving signals. In ad-

dition, although the output may have settled, the hold

capacitor has an additional lag due to the 300 series resis-

tor on the chip. This means that at the moment the “hold”

command arrives, the hold capacitor voltage may be some-

what different than the actual analog input. The effect of

these delays is opposite to the effect created by delays in the

logic which switches the circuit from sample to hold. For ex-

DS005692-5

ample, consider an analog input of 20 Vp-p at 10 kHz. Maxi-

Use 10-pin layout. Guard around C

is tied to output.

mum dV/dt is 0.6 V/µs. With no analog phase delay and 100

h

ns logic delay, one could expect up to (0.1 µs) (0.6V/µs)

= 60 mVerror if the “hold” signal arrived near maximum dV/dt

of the input. A positive-going input would give a +60 mV er-

ror. Now assume a 1 MHz (3 dB) bandwidth for the overall

analog loop. This generates a phase delay of 160 ns. If the

hold capacitor sees this exact delay, then error due to analog

delay will be (0.16 µs) (0.6 V/µs) = −96 mV. Total output error

is +60 mV (digital) −96 mV (analog) for a total of −36 mV. To

add to the confusion, analog delay is proportioned to hold

capacitor value while digital delay remains constant. A family

of curves (dynamic sampling error) is included to help esti-

mate errors.

A curve labeled Aperture Time has been included for sam-

pling conditions where the input is steady during the sam-

pling period, but may experience a sudden change nearly

coincident with the “hold” command. This curve is based on

a 1 mV error fed into the output.

A second curve, Hold Settling Time indicates the time re-

quired for the output to settle to 1 mV after the “hold” com-

mand.

Digital Feedthrough

Fast rise time logic signals can cause hold errors by feeding

externally into the analog input at the same time the amplifier

is put into the hold mode. To minimize this problem, board

layout should keep logic lines as far as possible from the

analog input and the C

pin. Grounded guarding traces may

h

also be used around the input line, especially if it is driven

from a high impedance source. Reducing high amplitude

logic signals to 2.5V will also help.

7

www.national.com